Preventing overspeed has always been the primary focus for turbine safety design

Now, as the industry has become more aware of the need for a more comprehensive approach to turbine safety, a refinement is underway that’s reflected in recent changes to industry standards such as API612 (Special-Purpose Steam Turbines for Petroleum, Chemical, and Gas Industry Services) and API670 (Machinery Protection Systems). This new sensibility highlights the importance of considering the performance of all components in the “turbine safety chain.”

The following is a summary of our interpretation of the revised standards, as they apply to turbine safety, specifically, overspeed detection and trip systems.

API 612

- Combining the turbine overspeed protection with the turbine shutdown system is allowed as long as the performance requirements can be met – controls must still be separate from the shutdown system and overspeed system.

- A new annex (Annex D) is included that provides the equations and method for calculating overspeed excursions (based on ASME PTC 20.2)

- The minimum requirement for trip oil system dump solenoids is two parallel, de-energize- to-trip valves. The standard recommends using a two-out-of-three or two-out-of-four arrangement to improve availability.

API 670

- Combining the turbine overspeed protection with the turbine shutdown system is allowed as long as the performance requirements can be met – controls must still be separate from the shutdown system and overspeed system.

- A new annex (Annex O) is included that provides the equations and method for calculating overspeed excursions for a steam turbine (based on ASME PTC 20.2)

- The standard requires a SIL study to determine the required redundancy and testing intervals. IEC 61511 and 61508 are cited for guidance in conducting the studies.

- A surge detection is required for axial compressors. This system must be separate from the anti-surge control system, but may be combined with the emergency shutdown system.

- ESD system shall record and store events with a 1 ms time stamp, retain the data for 30 days (or 10,000 events) in non-volatile memory and employ a first-in, first-out retention sequence.

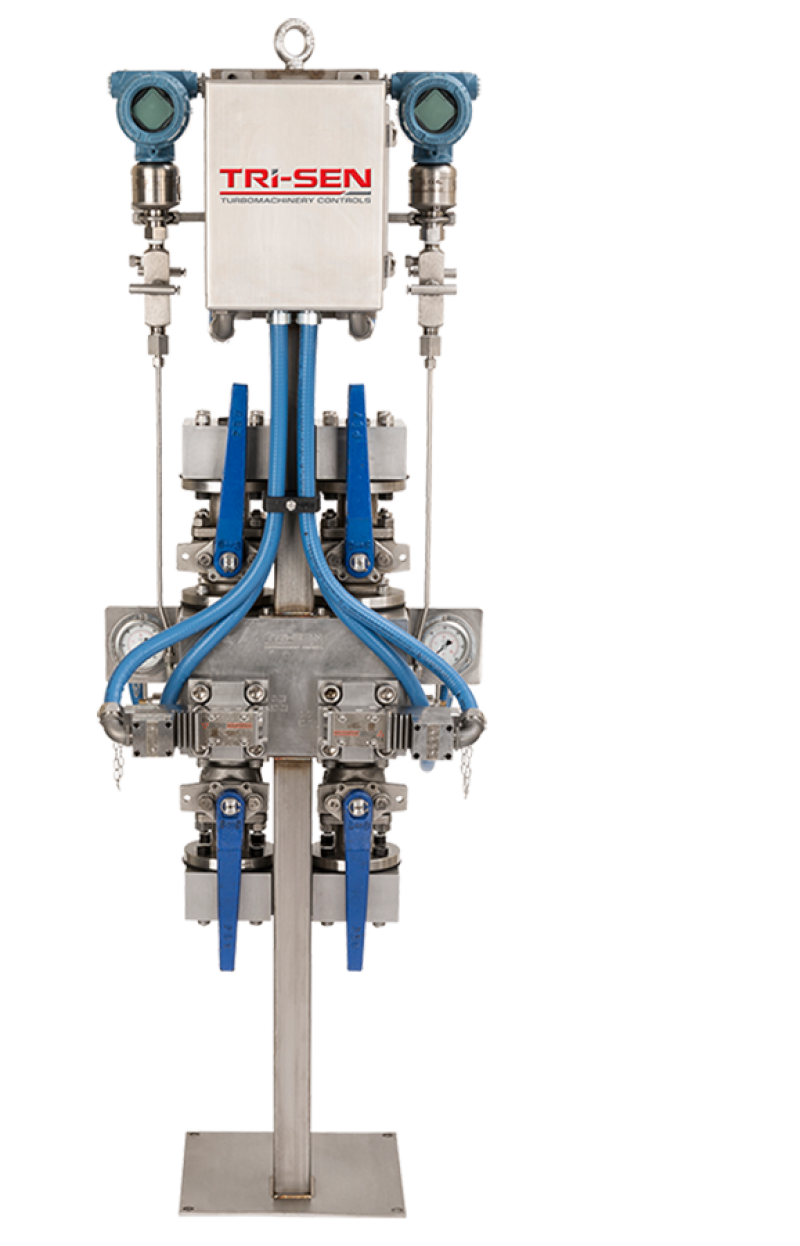

When it comes to protecting a critical turbine train, a TetraSentry hydraulic trip interface paired with the TSODS dedicated overspeed detection system, provides the most cost-effective, online-testable, and online-repairable safety system available.

TetraSentry

The TetraSentry is an online testable, online repairable hydraulic trip interface with SIL 3 reliability in an ultra-compact footprint designed specifically for turbomachinery applications. It is completely configurable, making it not only the most reliable but also the most adaptable hydraulic trip interface available.

For applications without a programmable logic solver with four outputs, a “manual test” configuration is available that allows the TetraSentry to interface with an independent “two or three output overspeed detection system.” The manual test configuration allows for full online testing of the TetraSentry. Optional block valves make this configuration online repairable.

For applications with a programmable logic solver (PLC), the TetraSentry can be configured with instrumentation to allow automatic testing.

For applications where a dedicated, configurable, electronic overspeed detection device (ODS) is most appropriate, we recommend the TSODS with integrated TertraSentry testing.

If we provide a PLC for the electronic overspeed protection system, we’ll also program the TetraSentry testing logic. If we’re not supplying a PLC or TSODS, and the TetraSentry has been configured for automatic testing, we’ll provide a “narrative” that describes the test.

TSODS

The TSODS is a TUV SIL-3-rated (with a 20-year proof test interval), API612 and API670 compliant, overspeed detection and protection system with ATEX and CSA/UL hazardous location certification. The TSODS is designed to replace a traditional mechanical trip-bolt or an obsolete electronic overspeed trip system on your steam or gas turbines, power turbines, (or other rotating equipment where ultra-reliable, precision overspeed detection and protection is essential).

DOWNLOADS

- Turbine Overspeed Trip Protection 1.291 MB pdf

- Understanding and Preventing Steam Turbine Overspeed 2.282 MB pdf