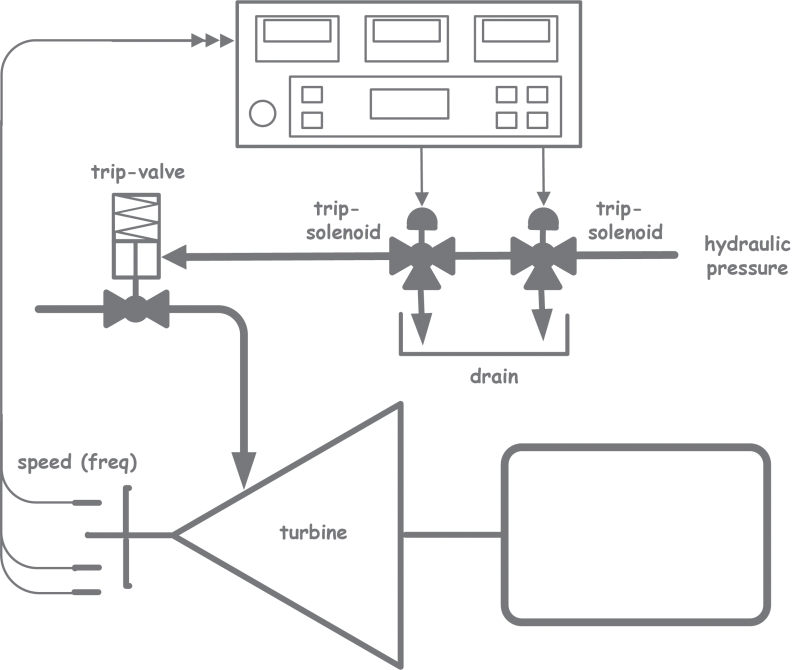

The TurboSafe is designed to replace a traditional mechanical trip bolt on steam or gas turbines, power turbines, and other rotating equipment. It’s purpose-built to provide reliable overspeed trip protection for rotating equipment using magnetic speed sensors to determine rotational speed. Like the other Tri-Sen configurable products, the TurboSafe includes an intuitive configuration interface, so it's easy to set-up and simple to operate.

Application Overview

The TurboSafe is a triplicated electronic overspeed trip device designed to API612 requirements.

The TurboSafe is designed to replace a traditional mechanical trip bolt on steam or gas turbines, power turbines, and other rotating equipment. It’s built to provide reliable overspeed trip protection for rotating equipment using magnetic speed sensors to determine rotational speed. The TurboSafe monitors up to three magnetic speed sensors and trips the turbine (de-energize trip outputs) if at least two of the sensors simultaneously detect an overspeed condition.

FEATURES

- 2003 (two-out-of-three voting) logic meets and exceeds the functional requirements of API 670 (Section 8.4)

- Easy on-line calibration and test of each trip setpoint and speed measurement circuit (using an external calibration source) provides simple set up and operation without fear of shutting down the turbine

- Total response time ≤ 40msec: elapsed time from overspeed detection, through decision making logic, to initiating the trip signal (output)

- Wide speed range of 100 to 25,000-RPM allows the TurboSafe to protect virtually any turbomachinery train

- Redundant power supplies: accepts one or two external 24 VDC power sources

- Accuracy to 0.02% of speed-the highest measurement accuracy available for overspeed protection

- Peak-hold on highest detected speed stored for event analysis

- Available in both a panel mount and a NEMA 4X enclosure

- Two independent Form-C trip relay outputs

- Three Form-C alarm relay outputs for each speed unit

- Modbus (slave) RS485 Serial Communications

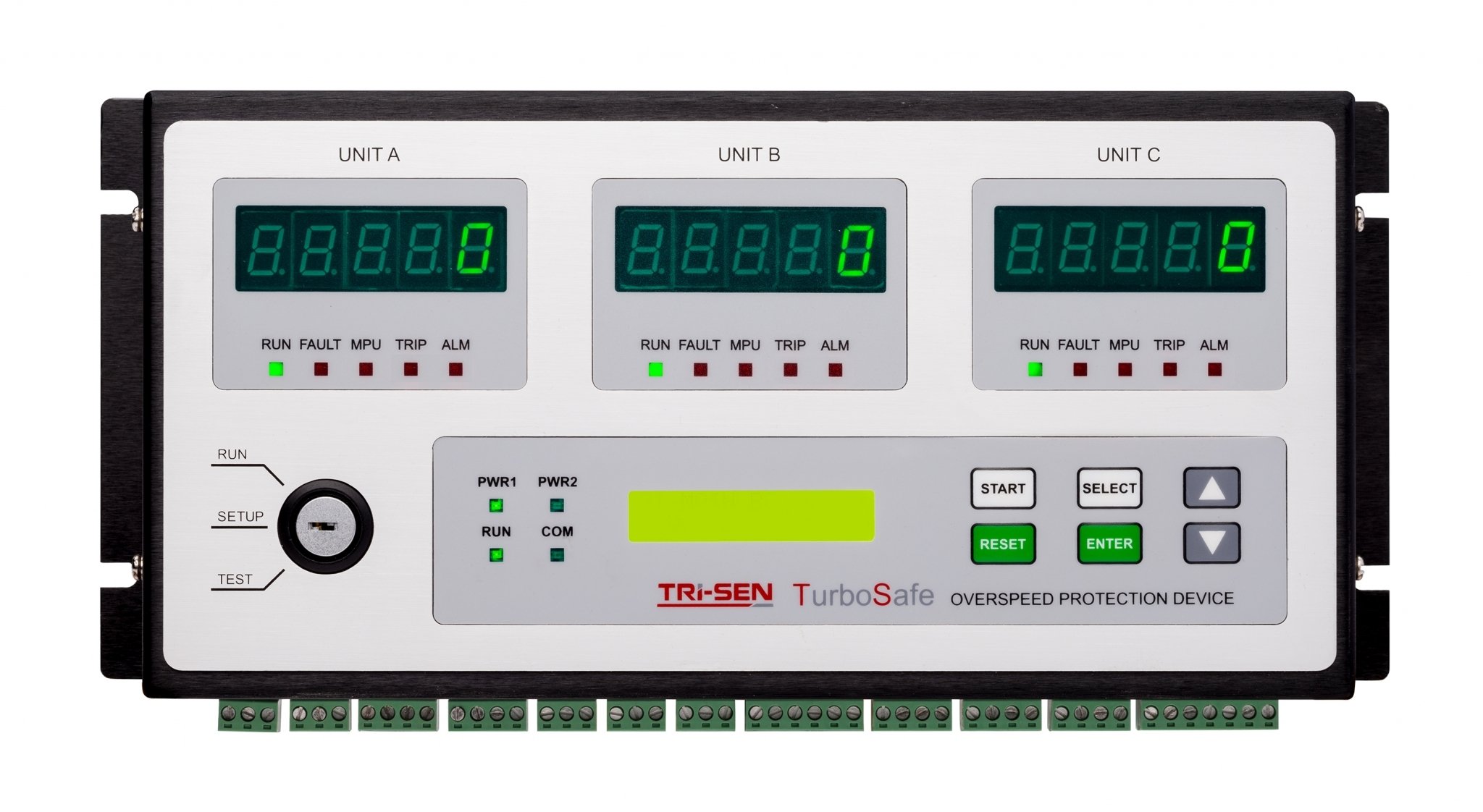

The TurboSafe is integrated into a NEMA4 panel mount enclosure for installation in an equipment cabinet. Optionally, the TurboSafe can be housed in a NEMA 4X enclosure, allowing it to be mounted outdoors on the turbine deck. The unit is self-contained with internal termination hardware. The operator interface includes a display area that consists of three 5-Digit LED speed displays, one 2 X 16-Character LCD and 19 individual LED status lamps. Operators input commands using six push-button keys and a three-position keyswitch.

PACKAGING

- NEMA 4 panel mount (standard)

- NEMA 4X stainless steel enclosure (optional)

- NEMA 4, painted steel "310SV + OST" (includes 310SV Turbine Control)

- NEMA 4X, stainless steel "310SV + OST" (includes 310SV Turbine Control)

INPUTS/OUTPUTS

- (2) Redundant 24vDC Power Inputs

- (3) Passive or active speed probes

- (2) Independent (form-C) trip relay outputs

- (3) Form -C (one for each speed measuring unit) alarm relay outputs

- (1) 4-20mA (voted) speed indication analog output

Configuring the TurboSafe couldn’t be easier- put in the keys, put the TurboSafe in setup and use the up and down pushbuttons to scroll through the intuitive configuration menu.

| Feature | Description |

|---|---|

| Pulse Inputs | (3) inputs, magnetic speed sensors (7Hz - 30KHz) |

| Digital Inputs | (2) inputs @ 24V DC, one remote reset, and one remote start |

| Feature | Description |

|---|---|

| Analog Outputs | (1) 4-20mA speed indication (output proportional to speed) |

| Digital Outputs | (5) outputs (c-form contacts) rated at 5 Amps @ 24VDC, two trip outputs, three alarm outputs |

| Feature | Description |

|---|---|

| Modbus (Slave) | RS485 Serial communications |

| Feature | Description |

|---|---|

| Power | 2 redundant 18-32V DC (power supplied externally) |